This is not a comprehensive guide, but simply a quick reference of some standards found in SMACNA.

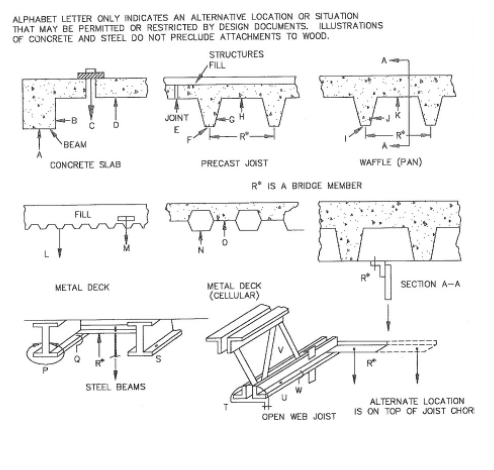

Hanging duct is difficult to standardize for obvious reasons, no jobsite is alike. The hanging systems is comprised of three parts: the upper attachment to the building, the hanger itself, and the lower attachment to the duct.

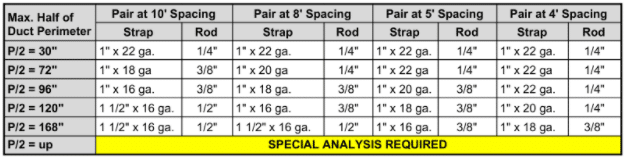

All horizontal ductwork must be supported every 8’-12’ depending on size, type of duct and style of hanger. Furthermore, horizontal ductwork must have a support within two feet of each elbow and within four feet of each branch intersection.

Rectangular risers should be supported by angels or channels secured to the sides of the duct with welds, bolts, sheet metal screws or blind rivets. Here again, for ducts over 30 inches wide, caution must be used in fastening the support to the sheet because the expansion of the sheet due to internal pressures will tend to tear the fasteners out. Riser support intervals should be at one or two story intervals, i.e., 12 ft to 24 ft, as suitable for loading. Another method is to support the riser by its reinforcing.

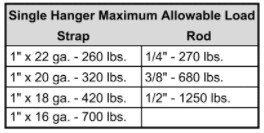

The selection of a hanging system should not be taken lightly not only because it involves a significant portion of labor, but also because an inadequate hanging system can be disastrous. In any multiple hanger system, the failure of one hanger transfers its load to adjacent hangers. If one of these fails, an even greater load is transferred to the next. The result is a cascading failure in which an entire run of duct might fall. Job specifications supersede these guidelines. When in doubt, ask your foreman or supervisor.

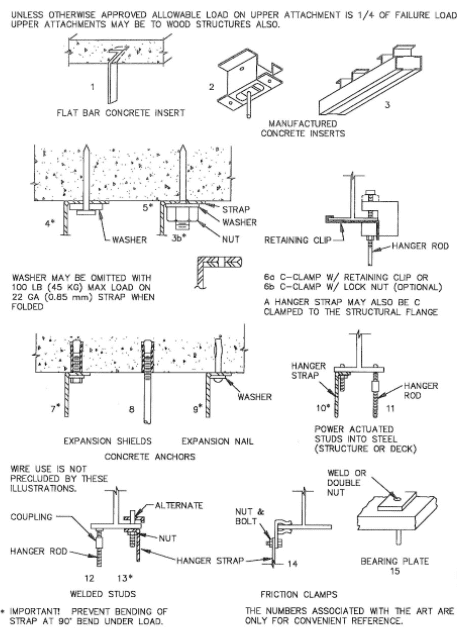

Upper attachments to structures shall have an allowable load not more than ¼ of the failure load. The weakest point in your hanger is often the upper attachment or the lower attachment to the duct, not usually the hanger itself.

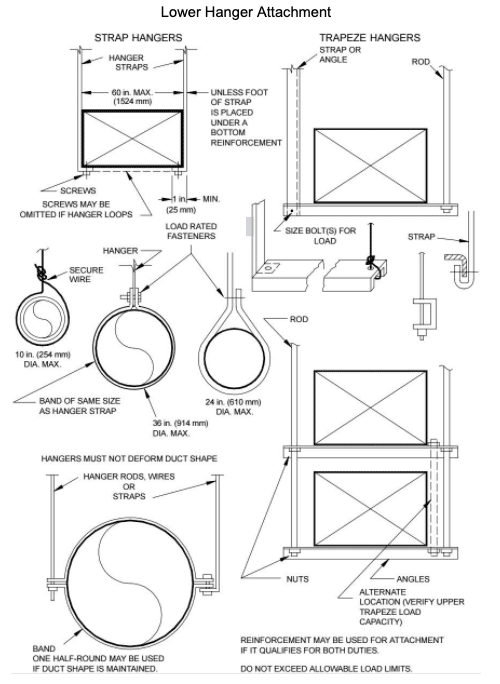

Trapeze hanger rods should be 2” from the sides of the duct. All hangers are to be level and straight. Strap should be flush with the side of the duct and screwed at the top corner of the duct, at the bottom corner, and underneath all within 1 inch of the corners. Strap wrapping under the duct should not exceed 1 ½”.

Upper Hanger Attachment