Vanstone Flange

This is a solution for large diameter pipe used for dust collection or any heavy gauge applications when other lighter gauge styles cannot perform. Flanges are heavy-duty iron angle rings, typically with a bolt pattern.

United Team Mechanical quality

Our HVAC Vanstone Flanges

Vanstone flanges are formed directly on the pipe, bending a 1/2″” lip at a 90º angle toward the outside of the duct. This 1/2″ flange holds an angle iron ring on the pipe, still allowing the ring to spin freely. The rings can then be easily aligned with other vanstone flange fittings or duct and bolt together, forming a very tight and strong connection.

Quality Suppliers

As always, the steel we buy is from American manufacturers and therefore held to a higher standard, G90. Furthermore, we source our angle iron rings from the most prominent, repeatable angle iron ring manufacturer in the country. Coupled with our certified welders and sheet metal workers, we can produce near-perfect vanstone flange ductwork. Furthermore, our 1/2″ lip is mechanically formed, making it square and flat to provide a tight, clean joint.

HVAC Fabrication and Manufacturing

Vanstone Flange Options

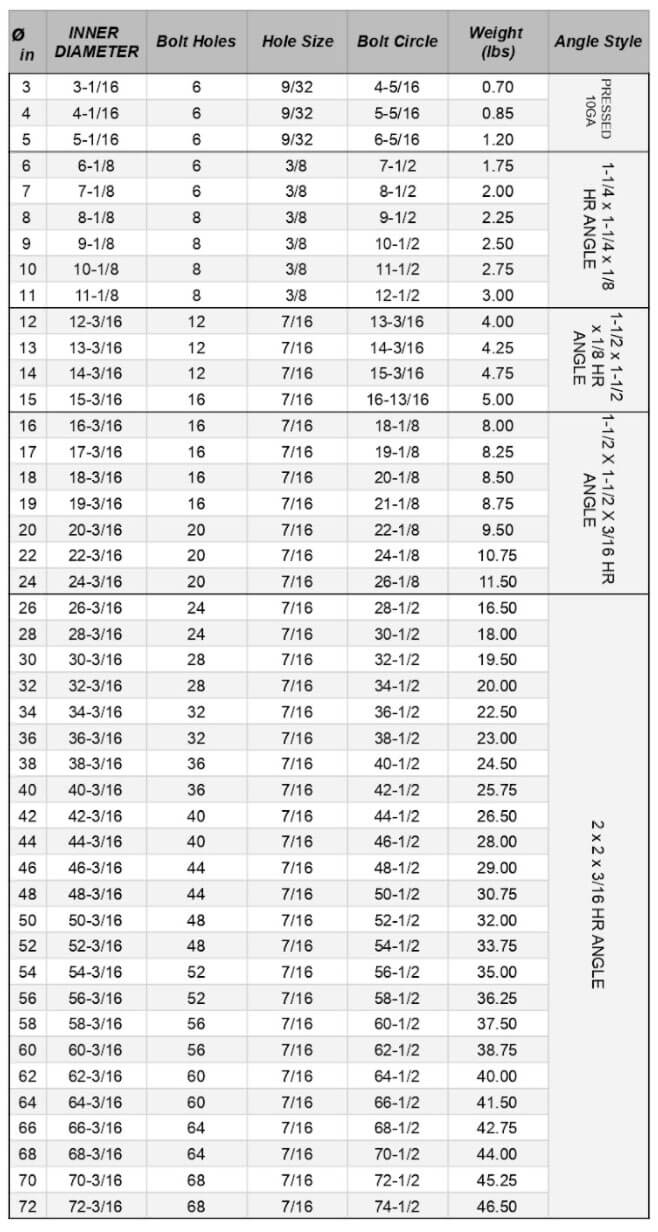

- Sizes range from 3″ – 120″ ø

- All pipe lengths

- All gauges

- All types of metal

- Galvanized, stainless, black iron rings

- Holes or no holes

Serving These Industries

Advantages of Vanstone Flanges

Strength

As pipes increase in diameter, the need for periodic support exponentially grows. Angle iron rings provide the most rigid support in the industry. The flanges are bolted together, pressing all the metal and gasket into a tight joint.

Custom

Although clamp together ducting excels in smaller diameters, anything above 24″ must be flanged. You have endless combinations of material, gauge, fitting, pipe length, pipe diameter that are all customizable.

Smooth and Leak-free

The interior of the pipe is smooth and does not have screws, rivets, or other obstructions in the airstream. Unlike spiral pipe, this seam is airtight and excels in the fine particulate collection.

Adjustable

Although the length of the pipe is more difficult to adjust, the loose rings allow for easy alignment of the ducting and fittings.

Reusable

These parts are able to disconnect and be reused when your shop floor layout changes or machine locations change. The parts you have already purchased can be reused.

Maintenance

Cleaning build ups or clogs can be found and fixed by breaking the connection. Remove the bolts on the connection, ensuring the other ducting is well supported, at the buildup, clean the ducting, and reconnect the ducting.

Frequently Asked Questions

How to cut and add a vanstone lip in the field?

Find the length of pipe you need, add 1/2″ to the length and cut the pipe. After the pipe is cut, slip the angle iron ring on so the flat portion of the ring is facing the cut. Hold the flange 1/2″ back from the cut edge, ensure the ring is square and secure it with c-grips. Then use a large hammer to bend the 1/2″ raw edge to a 90º angle, using the angle ring as back support.

How to install a vanstone flange?

Vanstone flange duct is typically heavier in gauge, larger in size, and weighs more than any other style pipe. We recommend using a material lift (hi-jack, forklift, duct jack) to support the material while you make the connection and support the duct. Vanstone flange duct can be hard to measure up – let us help you with our 3D CAD capabilities.

What style of pipe is vanstone flange duct?

Vanstone flange duct can either be spiral or longitudinal welded, which is completely dependent on the application. Spiral is cheaper and easier to make in longer lengths than a fully welded duct.

Do you seal between the flanges?

Vanstone lip connections can be sealed with caulking or gasket, again depending on the application.

How to cut heavy gauge ducting?

The easiest way is a grinder, sawzall, or metal circular saw. Each of these options, however, require specific personal protection equipment that is unique to those tools. NOTE: when cutting the pipe, don’t forget to add the 1/2″ to cut length to account for the flange.

Let’s Get Started on Your Next Project

We are Utah’s premier HVAC manufacturer, we take great pride in our work, let us know how we can help you with your next project.