Where We Serve

United Team Mechanical operates throughout the United States including the Hawaiian islands. With over 50 years experience, we have successfully completed over $500 million of projects across a broad spectrum of market segments.

Park City, UT

3 Kings Water Treatment Plant

Salt Lake City, Utah

Salt Lake City Airport

Mililani, Hawaii (NAVFAC)

Schofield Barracks

Brush, Colorado

Pawnee Power Plant

Henderson, Nevada

Southwest Water Reclamation Facility

Las Vegas, Nevada

Solids DeWatering

Riverton, Utah

EMC Dell

Green River, WY

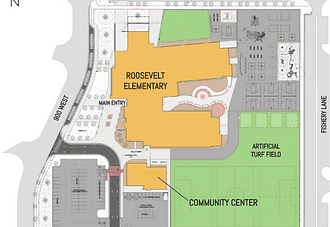

Monroe Intermediate School

Orem, UT

Utah Valley University

Ephraim, Utah

Snow College Science BLDG

Evanston, Wyoming

Wyoming State Hospital

Ely, NV

Robinson Mine

Colorado

Craig Nox Station

Oakland, California

Oakland California Temple

Waikiki, HI

Raising Cane’s Chicken

St. George, Utah

Tuacahn Center for the Arts

Our Projects

Let’s Get Started on Your Next Project

We are Utah’s premier HVAC manufacturer, we take great pride in our work, let us know how we can help you with your next project.